Целулоза Фармацеутски разред је важан ексципијенс у фармацеутској индустрији. Широко се користи у филмском премазу, лепљивом, лековном филму, масти, дисперзији, биљном капсули, преправном и контролисаном препарату за ослобађање и остале фармацеутске помоћи у фармацеутској индустрији. Основна технологија целулозе фармацеутских оцена намењена фармацеутским препарацијама са продуженим ослобађањем (укључујући препарате и препарате са контролисаним ослобађањем), и само неколико домаћих компанија је савладало и само неколико домаћих компанија савладало је производни капацитет целулозе етра за контролисане препарате за контролисано, ограничавајући препарате и наношењем фармацеутске индустрије. Фармацеутска оцена ХПМЦ је важна сировина за производњу препарата са продуженим и контролисаним ослобађањем. То је фармацеутски ексципијенс који подржава кључна истраживања и развој државе и у складу је са правцем развоја који подржава националну индустријску политику. Фармацеутски разред ХПМЦ је главни сировина за производњу ХПМЦ биљних капсула, која чини више од 90% сировина ХПМЦ постројења капсула. Припремљене постројење за биљке имају предности сигурности и хигијене, широке применљивости, без ризика од унакрсних реакција и високе стабилности, која задовољавају очекивања потрошача. Да би се испунили захтеви за сигурност и хигијене хране и медицине, то је један од важних додатака и идеалних замена за животињске желатинске капсуле. Потражња за биљним капсулама на иностраним тржиштима је брзо порасла. Моја земља је почела касно у области биљних капсула, са малим производима и продајом и великим потенцијалом за будућу потражњу тржишта. Последњих година држава је истраживала и бавила се предузећима које илегално произведу и користе неквалификоване капсуле, а побољшана је свест јавности о безбедности хране и дроге, што је промовисало стандардизоване операције и индустријску надоградњу домаће желатинске индустрије. Очекује се да ће постројење постројење постати једно од важних упутстава за унапређење шупље индустрије капсуле у будућности и биће главна тачка раста за потражњу за фармацеутском нивоом ХПМЦ на домаћем тржишту у будућности. Главна примена поља целулозе целулозе ЕТХЕП-а компаније ХПМЦ укључују филмски премаз, лепљив, лек, маст, дисперзију, препарат од поврће, препарат са контролисаним ослобађањем, итд.

У области медицине, препарати капсула имају очигледне предности преко таблета. Капсуле могу маскирати лош мирис дроге и лако је прогутати, тако да су они популарнији код потрошача; Поред тога, капсуле користе мање врста помоћних састојака, мање предмета за тестирање, нижих трошкова истраживања и развоја, веће истраживачке и развојне ефикасности и више фармацеутских производа. Ујутро ће период ексклузивности на тржишту патентираних лекова бити дуже, а профит нових лекова за фармацеутске компаније ће се значајно повећати. Истовремено, цена капсула је 25% -30% нижа од оне таблета. У 2007. години укупна глобална продаја капсула премашила је 310 милијарди капсула, од чега су 94% биле животињске капсуле, а 6% би биљне капсуле (око 18,6 милијарди капсула). У 2016. години, глобална продаја биљних капсула премашила је 100 милијарди капсула, од чега годишњи раст ХПМЦ шупљих капсула, стопа прелази 25%. У мојој земљи тржишни удио биљних капсула и даље не прелази 10%. Разлог је тај што велики производња ХПМЦ биљних капсула има одређене техничке потешкоће. У поређењу са развијеним земљама, повезане технологије за производњу биљних капсула у мојој земљи нису довољно зреле. Постоји мање предузећа, а излаз ХПМЦ биљних капсула је релативно мали, али с друге стране, као и земља и јавност посвећују сигурност шупље капсуле производе, биљне капсуле, биљне капсуле постаће један од важних упутстава за надоградњу шупље капсуле у будућности. Главна тачка раста потражње на тржишту за фармацеутску оцену ХПМЦ. Тренутно је и даље мало домаћих предузећа која могу да произведу целулозне етере. Представничка предузећа укључују главу Схандонг и Схандонг Руитаи. Стога, из оперативних података Схандонг-а, то се може видети да су подружнице компаније које производе целулозне етере и биљне капсуле у односу на биљне капсуле допринеле профитирању компаније и постају нова тачка раста за профит.

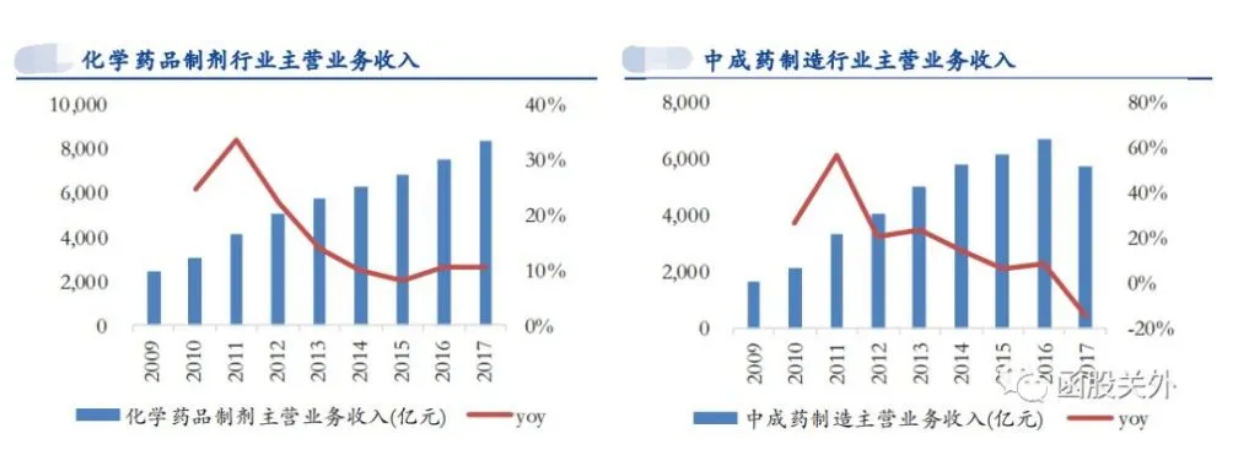

Фармацеутска индустрија моје земље је усред снажног развоја. У 2017. години предузећа изнад одређене величине у фармацеутској индустрији постигла су главни пословни приход од 2,9826 милијарди Иуана, а годишње раст од 12,20%. Ако фармацеутски ексципијенси чине 3% укупне излазне вредности фармацеутских препарата, процјењује се да је укупна излазна вредност домаћих фармацеутских средстава у 2017. години била око 52.162 милијарде јуана. Од 2009. до 2017. године, сложена годишња стопа раста главног пословног дохотка у индустрији хемијске фармацеутске припремне пословне раста је била висока као 16%, годишња раста раста главног пословног дохотка биофармацеутске производне индустрије била је висока као 20%, а годишња стопа раста главног пословног дохотка кинеске патентне медицине била је 20%. Стопа раста је висока као 16%, што показује брз развој фармацеутске производње моје земље, који ће возити брзи развој индустрије фармацеутских средстава.

Поред тога, подаци еуромонитора показују да је величина тржишне индустрије здравствене заштите у 2018. години била близу 160 милијарди јуана, годишње на годишњој стопи раста од 9,8%. Међу њима је потенцијална примена биљних капсула витаминима и додацима прехрани чинила је скоро 90%. Процјењује се да је глобална производња ХПМЦ меких капсула близу 100 милијарди капсула, која чини око 10% удела капсула, од чега 70% потиче од здравствених производа, попут витамина еких капсула, дубоког морског капсула који продају велике стране мултинационалне групе је око 400 јуана на 10.000 капсула, што је око 400 јуана на 10.000 капсула, што је око 400 јуана по 10.000 капсула, што је око 400 јуана на 10.000 капсула, што је око 400 јуана по 10.000 капсула, што је око 400 јуана на 10.000 капсула, што је око 400 јуана на 10.000 капсула, што је око 400 јуана на 10.000 капсула, што одговара постојећој величини тржишта 4 милијарде јуана. Са развојем низводне индустрије и повећања брзине пенетрације биљних капсула, величина тржишта ће се повећати у складу с тим.

Вријеме поште: феб-16-2023